All the American Flags On the Moon Are Now White

From gizmodo.com: NASA has finally answered a long-standing question: all but one of the six American flags on the Moon are still standing up. Everyone is now proudly talking about it. The only problem is that they aren’t American flags anymore. They are all white. The debate on the Moon flags has been going on […]

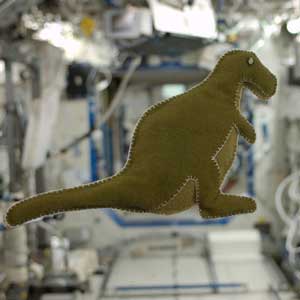

‘Made in space!’ Astronaut sews dinosaur toy from space station scraps

There is a dinosaur on board the International Space Station where there wasn’t one before. NASA astronaut Karen Nyberg, who since May has been working as a flight engineer as a member of the orbiting outpost’s resident crew, revealed the toy dinosaur floating on the space station on September 26. “Made in space!” Nyberg, an […]

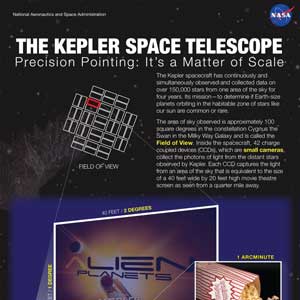

The Kepler Space Telescope: The equivalent of keeping your gaze steady on a grain of salt from a quarter mile away

From nasa.gov: Image credit: NASA Ames/Wendy Stenzel For four years, the Kepler spacecraft continuously and simultaneously observed and collected data on more than 150,000 stars. Its mission: to determine if Earth-size planets orbiting in the habitable zone of stars like our sun are common or rare. The stability of Kepler’s pointing is measured in degrees, […]

NASA Set to Fund World’s First 3D Food Printer

From worldindustrialreporter.com: NASA has announced that it will fund construction of the world’s first ever 3D food printer. The American space company has given a $125,000 grant to mechanical engineer Anjan Contractor, who has already designed the machine. And they hope it will eventually be able to provide food for astronauts on long-distance journeys through […]

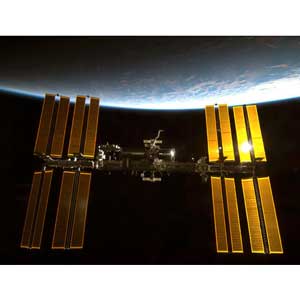

Astronaut Chris Hadfield Returns to Earth

By Kate Lunau from Macleans.com: Hadfield saw space and Earth as if they were brand-new and shared his experience aboard the ISS with millions. James Blair/NASA On May 13, as the Toronto Maple Leafs faced off against the Boston Bruins in Game 7 of their Stanley Cup playoff series, the Russian Soyuz spacecraft was undocking […]

The International Space Station will get its own 3D printer next year

Two of my favorite things! Space and 3D printing! By Mike Wall from SPACE.com: A 3D printer is slated to arrive at the International Space Station next year, where it will crank out the first parts ever manufactured off planet Earth. The company Made in Space is partnering with NASA’s Marshall Space Flight Center on […]

3D-printable food? NASA wants a taste

By Casey Johnston from ArsTechnica.com: Grant money goes to see if we can’t print perfect, nutritious food. Printing chocolate onto crackers. Not much, but it’s a start. SMRC. NASA has bestowed a $125,000 grant upon a research corporation to pursue the development of 3D-printable food, according to a report from Quartz. Anjan Contractor, who runs […]