This 1,600-Year-Old Goblet Shows that the Romans Were Nanotechnology Pioneers

Researchers have finally found out why the jade-green cup appears red when lit from behind By Zeeya Merali from smithsonianmag.com: The colorful secret of a 1,600-year-old Roman chalice at the British Museum is the key to a supersensitive new technology that might help diagnose human disease or pinpoint biohazards at security checkpoints. The glass chalice, […]

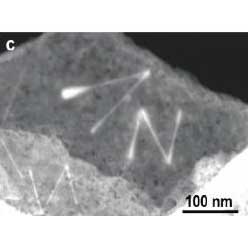

Scientists use electron ‘ink’ to write on graphene ‘paper’

By Lisa Zyga from Phys.org: Images taken by a scanning transmission electron microscope (STEM) of electron ink on graphene paper, showing the letter “N” and the symbol “Ʌ.” Credit: Wei Zhang, et al. ©2013 IOP Publishing Ltd. (Phys.org) —Nanoscale writing offers a reliable way to record information at extremely high densities, making it a promising […]